Introduction

Force main risks

A good understanding of the force main and its high-risk locations is an integral part of force main risk management. The vast majority of force main failures can be attributed to three main factors: internal corrosion, structural deterioration, and low sourcing velocity.

- Internal Corrosion. Over 60% of existing force mains are composed of ferrous materials like steel, cast iron, and ductile iron. The primary cause of failure in these force mains is internal corrosion due to hydrogen sulphide (H2S) gas.

- Structural Deterioration. Force mains have air release valves to prevent gas buildup at high points reducing the risk of sulphide corrosion. If an air release valve fails (or is not present), the resulting sulphide corrosion can gradually deteriorate metallic piping and valves, ultimately causing force main failure.

- Low Sourcing Velocity. Too low flow in force mains can lead to deposit build up which will restrict capacity and can be a risk for abrasion over time.

Pipers® inspection tool

Pipers®, INGU’s free-floating inspection tools, provide a comprehensive assessment of force mains. Pipers® effectively identify gas pockets (and leaks), determine the hydraulic grade line, and perform a magnetic inspection in a single inspection. The free-floating design allows Pipers® to navigate the force main’s flow without getting stuck in air release valves, tees, or deposits.

- Gas pocket detection. The Pipers® record sounds caused by gas pockets, pumps, and other noise sources in the pipeline. Gas pockets are usually louder than the background noise in the pipeline and can be confirmed by the specific spectral signature at its location.

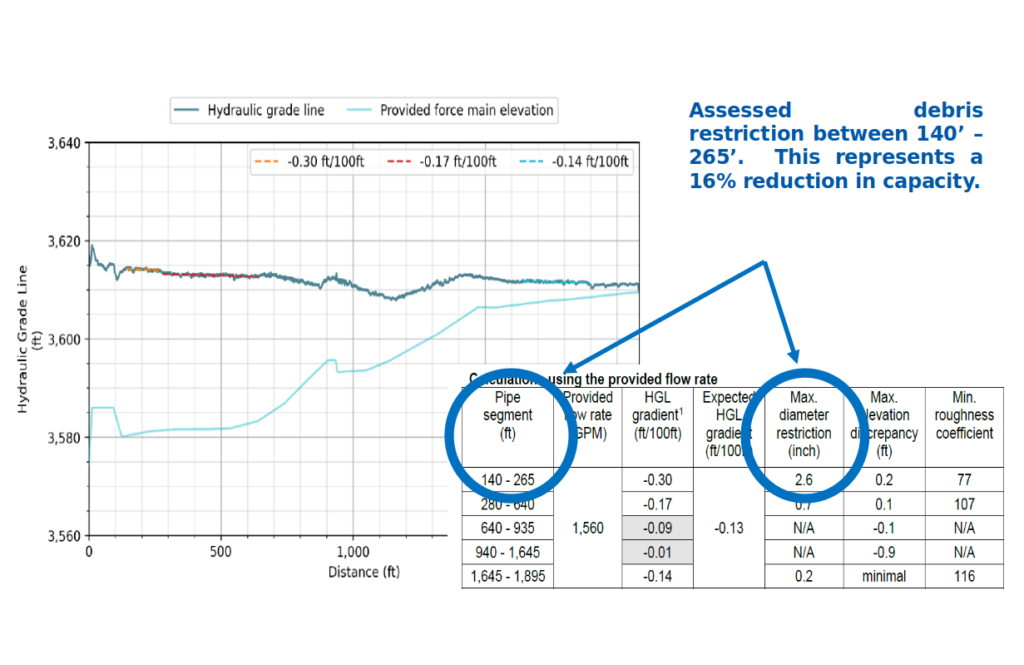

- Hydraulic grade line inspection. The hydraulic grade line indicates the amount of frictional pressure loss throughout the force main, where regions of the hydraulic grade line with a steeper slope experience more flow friction suggesting increased internal surface roughness and/or diameter restrictions.

- Magnetic inspection. Pipers® measure the magnetic flux density inside pipelines. These measurements allow for the identification of material changes, pipeline features (e.g. air release valves and casings), and deterioration of metallic piping.

Case study (SFE Global / Oregon City)

After performing a condition assessment of their sewer pump station, Oregon City considered the force main the likely candidate for why they were seeing reduced pumping capacity on one of its crucial sewer force mains, a 16-inch ductile iron pipe stretching 2,300 feet. The city needed to address two primary concerns to ensure the optimal performance of this vital infrastructure:

- Air Pockets: Were there air pockets trapped within the force main that could be impacting the flow capacity or pump station performance?

- Debris and Tuberculation: Was there considerable tuberculation or other debris obstructions within the pipe that could be reducing its flow capacity?

The presence of air pockets could lead to inefficiencies and potential corrosion due to the accumulation of hydrogen sulfide gas, while debris and scale build-up could significantly reduce the pipe’s capacity, impacting the overall efficiency of the sewer system.

They decided to approach SFE Global, our local partner, to perform a Pipers® inspection. SFE Global created a case study describing the results of the force main inspection.

The detailed assessment conducted by SFE Global using INGU Pipers® provided crucial insights into the condition of the sewer force main:

- No Leaks Detected: The pipeline was found to be free of leaks, ensuring the integrity of the pipe.

- Air/Gas Pockets Detected: Several significant air pockets were located, particularly near the bridge crossing high point, necessitating targeted interventions to prevent corrosion.

- Debris and Scale Build-Up: The assessment highlighted 125 feet of the force main near the pump station with reduced capacity due to debris or scale.

The partnership with SFE Global and the utilization of INGU Pipers® technology allowed the Oregon City to gain a comprehensive understanding of their sewer force main’s condition. By identifying air pockets and debris build-up, the city could take proactive measures to maintain and improve the pipeline’s efficiency and longevity.